Our client, Ahmedabad based start-up company, aimed to develop a solution where his customer can enhance their production capabilities while aligning with sustainable practices. They sought to develop a groundbreaking R3 Units which is Ecofriendly harmonization of energy recovery and systematic drying technology that would be the first of its kind in India, addressing both efficiency and environmental impact.

The Client Faced Several Challenges:

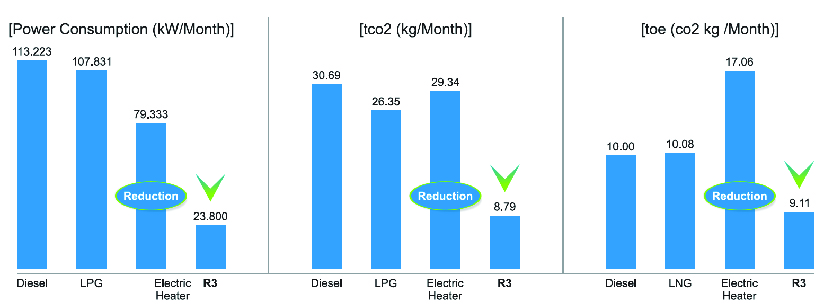

- High energy consumption in their existing dying processes.

- Significant CO2 emissions contributing to their carbon footprint.

- Maintenance issues with current systems leading to downtime.

- Lack of precise temperature control, affecting print quality.

We partnered with the client to design and implement solution with Danfoss SZ110 scroll compressor and allied controls (Expansion valve, Filter Drier, Sight Glass, Solenoid Valve, Pressure controls, Temperature sensors) that addressed these challenges while incorporating key unique selling propositions (USPs). Danfoss and FX technical team played important role to run the tests for worst operating conditions and got it qualified.

Key Features & Benefits

- Sustainability: The solution operates on sustainable practices, significantly reducing environmental impact.

- Green Energy: Utilizes renewable energy sources, ensuring a reduced dependency on fossil fuels.

- Reduced CO2 Emissions: Engineered to lower CO2 emissions by up to 70%, contributing to the client’s sustainability goals.

- Reduced Maintenance: The design includes self-regulating components that require minimal intervention, ensuring constant operation without unexpected breakdowns.

- Energy Savings: The machine is designed to be 50% more energy-efficient compared to traditional methods, resulting in substantial cost savings.

- Precise Temperature Control: Advanced controls provide precise temperature management, ensuring uniform drying and high-quality prints.

- Heat Recovery from Exhaust Air: The system captures and reuses heat from exhaust air, further enhancing energy efficiency.

- Air Recycling in Hot Room: Contaminated air is expelled and treated for recycling, improving air quality in the workspace.

- Safety 100% On Board: Comprehensive safety features, including automated shutdown protocols and real-time monitoring systems, ensure a secure working environment.

- Pre-defined ROI: The investment model included a clear return on investment strategy, allowing the client to anticipate financial benefits over time.

Implementation

The implementation involved a multi-phase approach:

- Prototyping: Developed a prototype to test key functionalities, especially energy savings and temperature control.

- Testing & Optimization: Conducted rigorous testing to refine the machine’s performance, focusing on reducing emissions and improving energy efficiency.

- Training & Support: Provided comprehensive training for the client’s staff on operating and maintaining the new system.

Results

- Operational Efficiency: The new R3 unit reduced operational costs significantly, with a clear 50% reduction in energy usage.

- Increased Production: Improved speed and quality of drying processes led to a 30% increase in production capacity.

- ROI Realization: The client reached the projected ROI within 18 months, exceeding initial forecasts.

The successful development and implementation of the R3 unit have positioned our client as a pioneer in the printing industry in India, demonstrating a commitment to sustainability and innovation. This project not only enhanced their operational efficiency but also set a new standard for environmental responsibility in the sector.

By combining cutting-edge technology with sustainable practices, we were able to deliver a solution that not only meets but exceeds the expectations of modern printing operations.